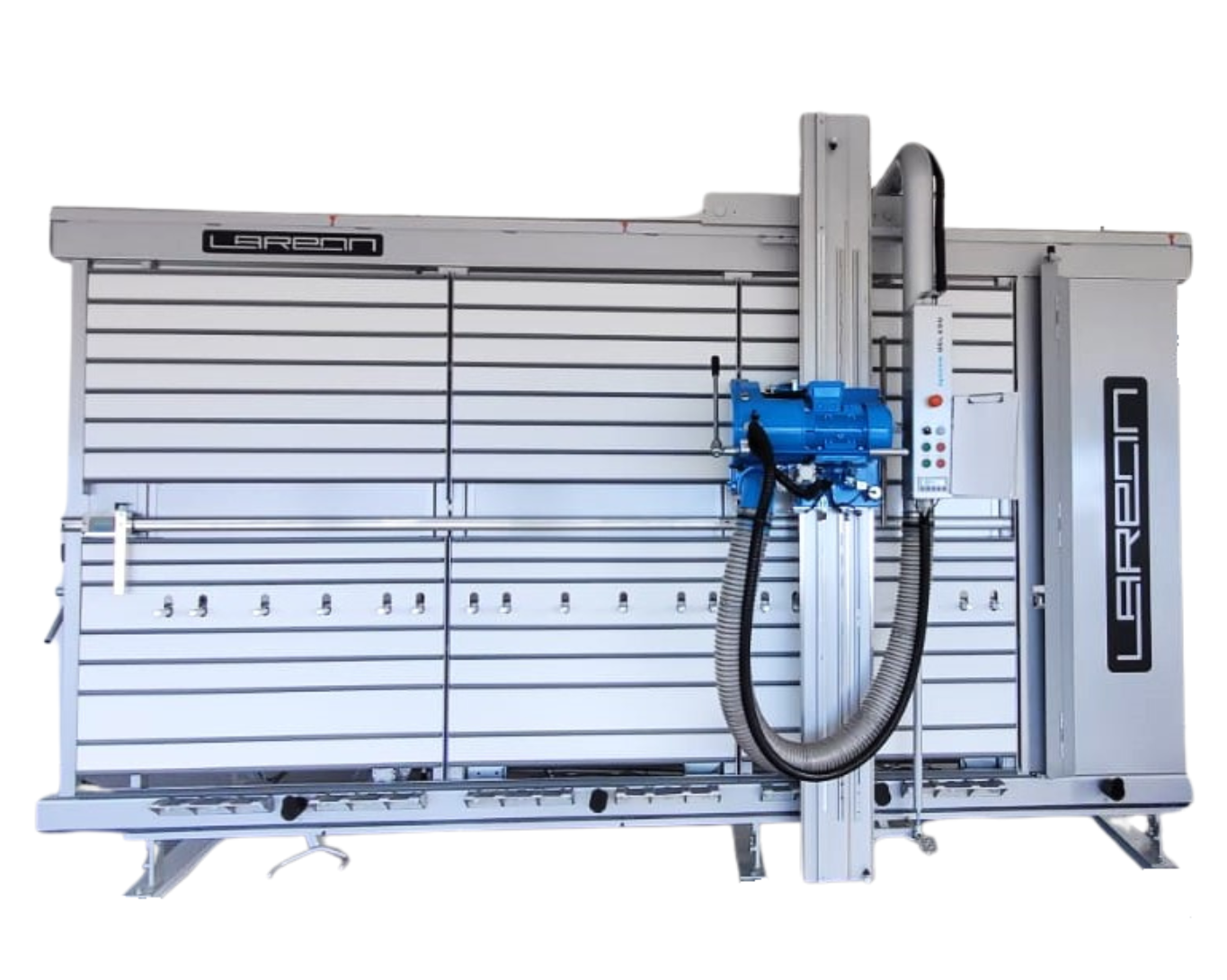

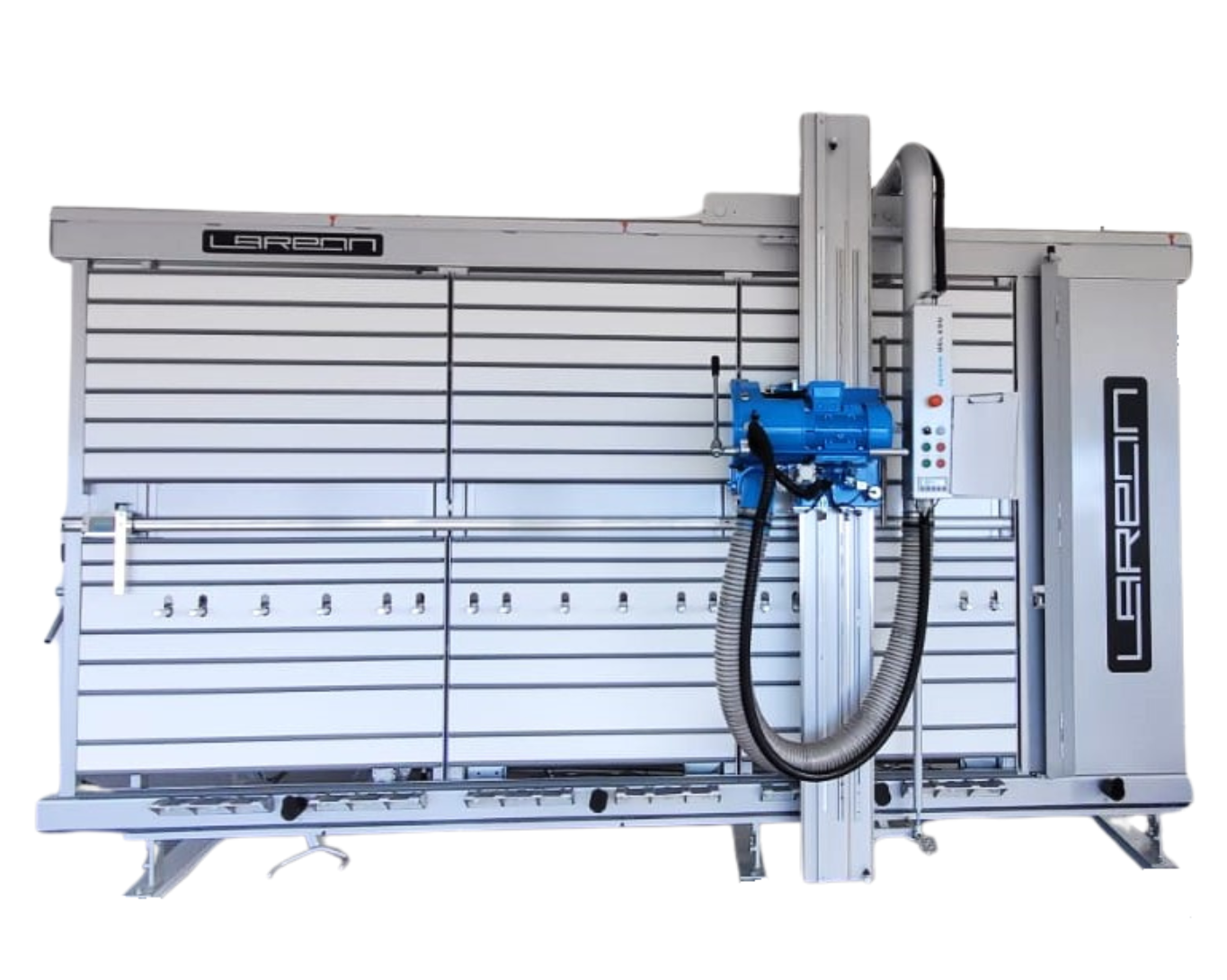

250GEL OPTIMA

Vertical panel saw with automatic plunge and carriage clamping

Product name : 250GEL OPTIMA

Enhanced ergonomics: reduced cutting effort and increased productivity!

Request a quote

Product name : 250GEL OPTIMA

Enhanced ergonomics: reduced cutting effort and increased productivity!

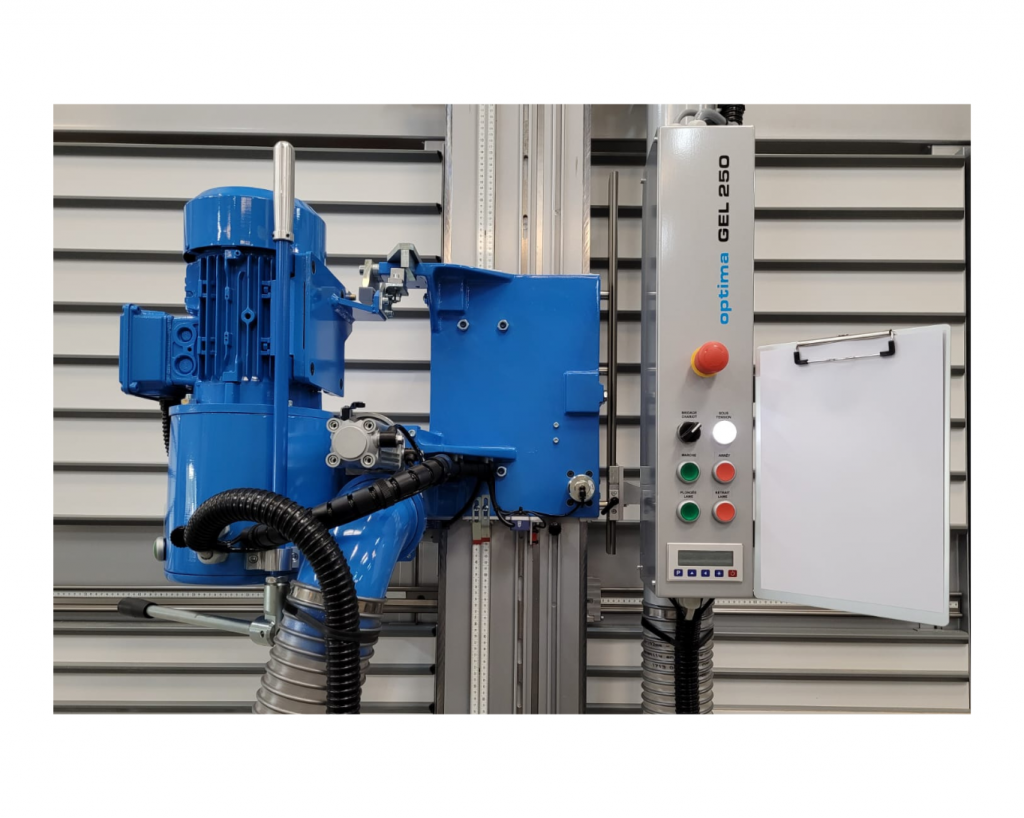

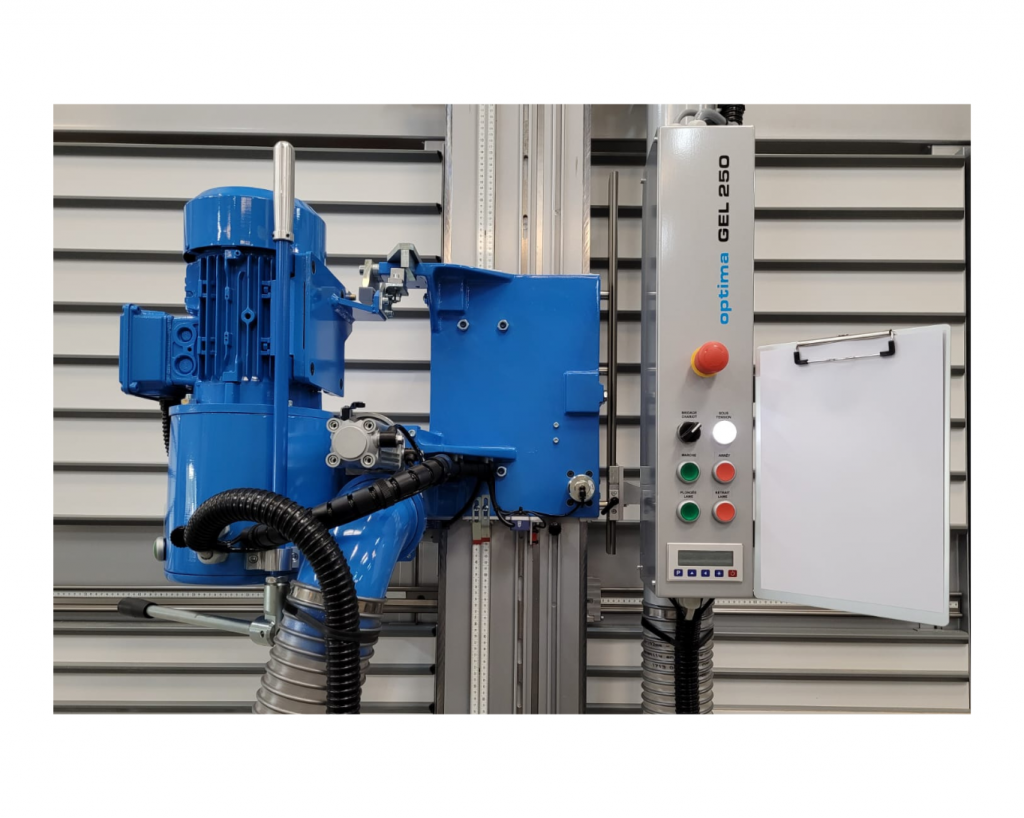

Request a quoteThe saw is locked in the horizontal position simply by tilting it.

Plunges into the material to be cut, either via the actuator on the console or directly on the saw block.

Monobloc frame in mechanically welded steel

7.5 HP 400 V three-phase motor with electromagnetic brake

24 V low voltage control circuit

250/30 mm carbide blade

Blade rotation speed 4500 rpm

Maximum cutting depth 80 mm

Automatic retraction of panel support slats

Retractable transport rollers with 3 control pedals

Foldable intermediate rail along the entire length

Repeatable cutting stop 650 mm

5 horizontal cut programming stops

Optimized sawdust collection system at the rear of the panels, consisting of:

4 collection chutes for each of the 4 vertical cutting points, connected to a collector integrated into the frame

1 retractable side collection chute for horizontal cuts

1 pneumatically controlled flap automatically opens the vertical chutes or the horizontal chute depending on the position of the blade

2 side sawdust outlets ø 100 mm for connection to an external extraction unit

5 cutting formats

250GEL OPTIMA 3116: 3100 x 1600

250GEL OPTIMA 3119: 3100 x 1900

250GEL OPTIMA 4121: 4100 x 2100

250GEL OPTIMA 5022: 5000 x 2200

250GEL OPTIMA 7022: 7000 x 2200

Presence detectors on intermediate rail and lower base (to ensure secondary suction in horizontal cutting)

5.5 HP 2-speed brake motor

Electronic speed variator

Pneumatic blade immersion and pneumatic clamping of the carriage by push button

Transport rollers every 350 mm

Pneumatic lifting of transport rollers

Blade lubrication device

Lower length ruler with retractable stop

Digital display of horizontal cutting dimensions

Digital display length stop

Depth stop for grooving

Kit for grooving composite panels

Marine packaging

Zephyr vacuum cleaner